Alumina Ceramic Linings & Plates

Second only to diamond in hardness (+9 Mohs) alumina ceramic liners provide outstanding wear resistance to erosion and corrosion problems in a variety of hostile environments. Alumina ceramic liners will typically outlast lower grade materials commonly used to line or protect processing and material handling equipment, including stainless steel, carbon steel, basalt and AR plates by factors of 3 to 15 times. With an economical cost vs. wear-life ratio makes it one of the most widely used abrasion resistant materials in the industry.

Our ceramic liner materials are offered in a variety of shapes, sizes and grades to fit almost any application and are available through shop installation, at your site by our field service crews or for purchase from our industry leading inventory program. Alumina Ceramics are also used in our VulcanPlate™ Wear Plates and our VulcanHose™ Abrasion Resistant Hoses.

Advantages

Commonly referred to as ”pre-engineered” systems, a kit of ceramic materials can be manufactured to minimize installation time in many complex shaped substrates. Cones, pipes and transition linings for example can be installed in hours versus cutting these diamond hard tiles after they are fired to fit the shape or around holes and doors or segments of pipe.

- Maximum use temperatures over 2,000° F

- Zero porosity

- Half the weight of steel

- Variety of shapes and sizes readily available

- Economic installation in our shop or in the field

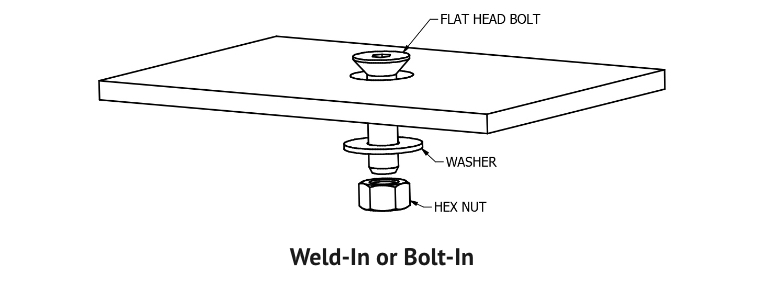

- Variety of adhesion methods

Applications

- Pipe liners in mitered elbows

- Tees

- Laterals and spools

- Grain chutes and hoppers

- Cyclones

- Classifier cones

- Wear panels

- Valves

- Fans and fan housings

- Rotary airlocks and feeders

- Material augers and troughs

Stock Tiles

With a wide variety of sizes available we can offer quick turnarounds for many projects.

| Plain Tile (PL) | ||||||

|---|---|---|---|---|---|---|

| Thickness | ||||||

| Width | Length | 1/8 | 1/4 | 1/2 | 1 | 2 |

| 1/2 | 1 |  |

|

|||

| 1 | 1 |  |

|

|

||

| 1 | 2 |  |

|

|||

| 1 | 3 |  |

|

|||

| 1 | 4 |  |

|

|||

| 1 | 6 |  |

|

|||

| 2 | 2 |  |

|

|

||

| 2 | 4 |  |

|

|

||

| 2 | 6 |  |

|

|

||

| 4 | 3 |  |

|

|

|

|

| 4 | 4 |  |

|

|

|

|

| 4 | 6 |  |

|

|

|

|

| 4-1/2 | 9 |  |

||||

| Weld-Able Tile (WS) | ||||||

|---|---|---|---|---|---|---|

| Thickness | ||||||

| Width | Length | 1/4 | 1/2 | 3/4 | 1 | 2 |

| 2 | 4 |  |

|

|

||

| 2 | 6 |  |

|

|

|

|

| 4 | 3 |  |

|

|

||

| 4 | 4 |  |

|

|||

| 4 | 6 |  |

|

|

|

|

| 4-1/2 | 9 |  |

|

|||

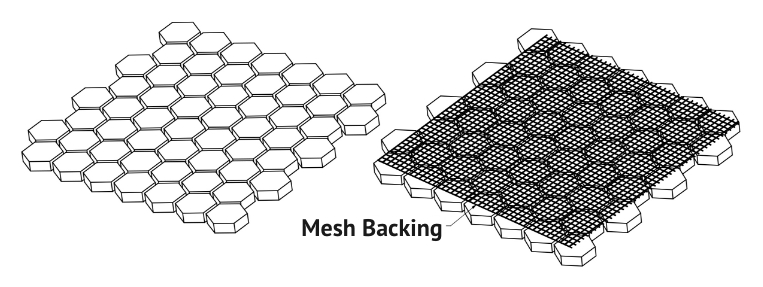

| Hex Mesh (Hex) | |||||

|---|---|---|---|---|---|

| Thickness | |||||

| Width | Length | 1/8 | 1/4 | 3/8 | 1/2 |

| 6 | 6 |  |

|

|

|

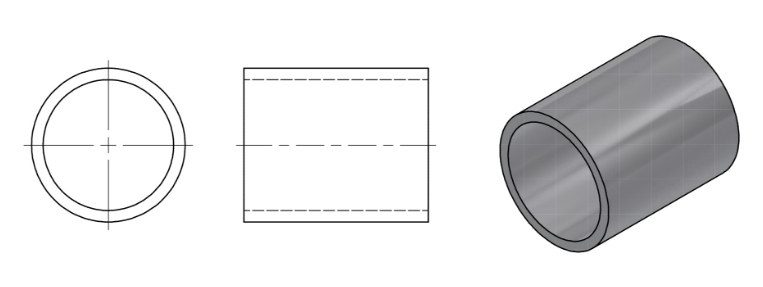

| Iso-Pressed Cylinders | ||

|---|---|---|

| ID | OD | Length |

| 2.000 | 2.500 | 6.500 |

| 2.063 | 2.000 | 6.542 |

| 3.000 | 3.500 | 6.000 |

| 3.000 | 3.500 | 6.500 |

| 4.250 | 5.000 | 6.000 |

Speak With a Specialist

If you have an application to discuss, or need technical assistance, please fill out the form below.