Wear Compounds & Abrasion Resistant Coatings

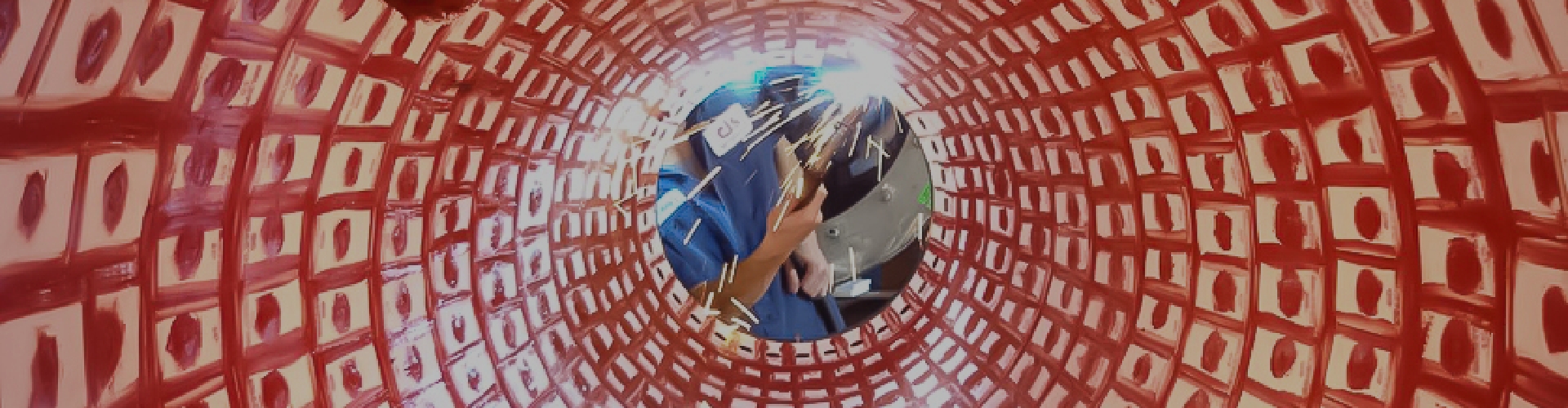

C.L. Smith Industrial Company offers a family of wear compounds and abrasion resistant coatings that have proven to last extended periods in many applications even though they are generally considered a short term solution. The abrasion and corrosion resistant compounds start off with our specially formulated epoxies and are loaded with alumina ceramic or silicon carbide beads suspended in the epoxy resin. They provide excellent protection for use in chutes, elbows, cones and other material processing equipment.

- CLS-101 Fast Set is based on CLS-70-4 epoxy loaded with ceramic beads

- CLS-202 Regular Set is based on CLS-773 epoxy loaded with ceramic beads

- CLS-303 Regular Set is based on CLS-773 epoxy loaded with silicon carbide beads

- CLS-404 Heat Resistant is based on CLS-63 epoxy loaded with ceramic beads

- CLS-504 Heat Resistant is based on CLS-63 epoxy loaded with silicon carbide beads

- CLS-1100 High Temperature is a custom formula loaded with micro ceramic beads

Specialty Items

With custom solutions at the forefront of addressing everyday erosion and corrosion problems we continuously look for ways to incorporate those products initially designed for a very specific application into our family of adhesives and wear compounds.

CLS-808 Brushable Ceramic

CLS-808 Brushable Ceramic is a brushable epoxy coating blended with abrasion resistant ceramic fillers to provide a durable protective barrier on surfaces subjected to wear and abrasion. CLS-808 low odor, contains no VOC’s or solvents and is waterproof and resistant to most chemicals and solvents. With a thick creamy paste consistency it is easy to apply by brush to most surfaces and allows for vertical and overhead application. Multiple colors available for creating layered surface wear indicators. Ideal for use on:

- Mixing vessels

- Hoppers and chutes

- Pump casings

- Pneumatic conveyors

- Grain bins

- Dust collection systems

- Cyclones

- Augers and troughs

- Wear plates

- Brick corners and transition areas

- Fan and impeller blades

- Piping, elbows, laterals

CLS-909 High Impact

CLS-909 High Impact is a flexibilized epoxy gel blended with abrasion resistant ceramic beads to provide a high-impact resistant, asphalt looking surface where severe wear and impact are problematic. CLS-909 is waterproof and resistant to most solvents and chemicals. The thick non-sag paste consistency will allow for vertical and overhead patching and by building up multiple layers thickness can exceed 1 inch. Ideal for use on the same applications as CLS-808.

CLS-1201

CLS-1201 is a high solids steel filled matrix for repair of worn steel surfaces and components. CLS-1201 is waterproof and contains no VOC’s or solvents and the non-sag paste allows for overhead or vertical patching. The excellent high strength epoxy compound is machinable, can be drilled and tapped and has a 200°F service temperature. Ideal for use on:

- Drive shafts

- Grain bins and hoppers

- Worn metal surfaces

- Slurry pumps

- Mixing blades

- Dust collection systems

All products are offered in (2) quart, (2) gallon and (10) gallon kits. Coverage for a (2) gallon kit is approximately 12.8 square feet at 1/4" thick.

Physical Properties

| CLS-101 | CLS-202/CLS-303 | CLS-404/CLS-505 | CLS-1100 | |

|---|---|---|---|---|

| Tensile Strength (ASTM D-638) |

2,800 psi | 8,300 psi | 6,300 psi | 6,300 psi |

| Compressive Strength (ASTM D-695) |

10,600 psi | 10,600 psi | 14,000 psi | 14,000 psi |

| Shore D Hardness | 80-85 | 80-85 | 85-90 | 85-90 |

| Pot Life @ 77° F (100 grams) |

6 minutes | 35 minutes | 30 minutes | 30 minutes |

| Cure Time @ 77° F | As little as 15 minutes | 16-24 hours | 4-5 hours | 4-5 hours |

| Service Temperature | 180° F (Dry) or 130° F (Wet) |

180° F (Dry) or 130° F (Wet) |

350° F (Dry) or 300° F (Wet) |

350° F (Dry) or 150° F (Wet) |

| Intermittent Temperature | 225° F (Dry or Wet) | 225° F (Dry or Wet) | 400° F (Dry) or 350° F (Wet) |

450° F (Dry or Wet) |

| Mix Ratio | 1:1 by volume | 1:1 by volume | 1:1 by volume | 2:1 by volume |

| Mixed Viscosity | Heavy Paste | Heavy Paste | Heavy Paste | Heavy Paste |

| Shelf Life (factory sealed containers) |

12 months | 12 months | 12 months | 12 months |

| Wear Material | Ceramic Beads | 202 Ceramic Beads / 303 Silicon Carbide Beads |

404 Ceramic Beads / 505 Silicon Carbide Beads |

Micro Ceramic Beads |

Please call C.L. Smith Industrial Company and speak with your Sales Representative for your specific wear compound needs.

Speak With a Specialist

If you have an application to discuss, or need technical assistance, please fill out the form below.