RTV Adhesives

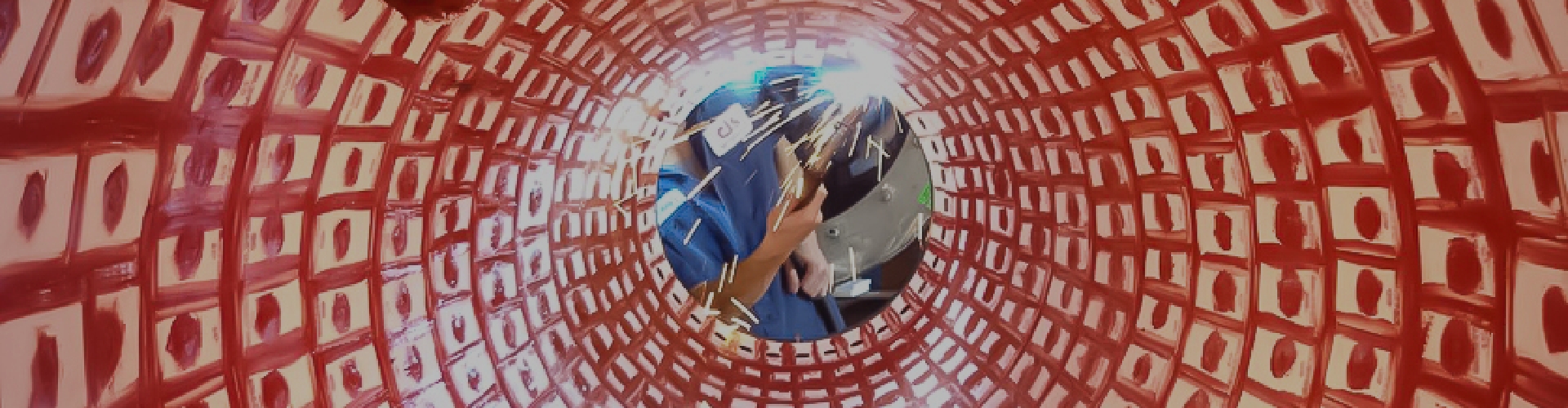

C.L. Smith Industrial Company offers a variety of RTV silicones for all your adhesive and sealing needs. Our specially formulated materials can be used in a wide variety of applications from environments that are cold and wet to others that are hot and dry.

All products are formulated and well suited for installing abrasion resistant materials but are also excellent for other areas of your operation that may need attention.

CLS-111 (White), CLS-222 (Clear)

and CLS-444 (Red Hi-Temp)

CLS-111 (White), CLS-222 (Clear) and CLS-444 (Red Hi-Temp) are single component 100% silicone adhesive sealants which cure to a tough, rubbery solid at room temperature on exposure to water vapor in the air (acetoxy cure). These RTV’s adhere to clean substrates such as ceramic, metal, glass, most woods, painted surfaces, can be applied overhead without sagging and retain permanent flexibility with excellent weatherability. Primarily used as our workhorse RTV’s for bonding wear materials but also great for:

- Formed in place gaskets

- Sealing windows and high efficiency furnaces

- Adheres to metal, glass, most woods and painted surfaces

- CLS-444 is good for encapsulating heating elements in appliances, bag filters on smokestacks and manifolds.

- Conforms to MIL Spec MIL-A-46106A, Amend 2 Type 1 and FDA Regulation No. 21 CFR 177.2600

CLS-555

CLS-555 is another RTV option that has a neutral/oxime/non-acid based cure (low odor). Bonds a wide variety of materials, is VOC compliant and meets Green Building Standards. Primarily used for bonding wear materials but also offers the following benefits:

- All weather performance

- Non-corrosive

- Other industrial applications include;

- Sealing openings and exterior surfaces

- Sanitary seals

- Industrial gaskets

- Plumbing, roofing and HVAC

- Available in multiple colors

All products are offered in convenient 10.3-ounce tubes, (1) gallon and (5) gallon pails.

Physical Properties

| CLS-111 / CLS-222 | CLS-444 | CLS-555 | |

|---|---|---|---|

| Color | White/Clear | Red | White |

| Specific Gravity | 1.04 | 1.04 | 1.04 |

| Durometer, Shore A | 26 | 32 | 15 |

| Extrusion Rate | 330 g/min | 350 gms/min | 500 gms/min |

| Skin Over / Track Over Time | 10-20 minutes | 6-15 minutes | 12-25 minutes |

| Cure Time | 24 hours | 24 hours | 24 hours |

| Tensile Strength | 363 psi | 350 psi | 190 psi |

| Elongation | 640% | 640% | 650% |

| Peel Strength: Aluminum (Steel) | 18 (20) piw | 18 (20) piw | n/a |

| Dielectric Strength kv/mm (v/mil) | 20 (500) | 20 (500) | 20 (500) |

| Dielectric Constant @ HZ | 2.9 @ 60 | 2.9 @ 60 | 2.7 @ 96 |

| Service Temperature | -62° F to 400° F | -85° F to 500° F | -62° F to 400° F |

| Intermittent Temperature | 425° F | 600° F | 450° F |

| Shelf Life (factory sealed containers) | 24 months | 24 months | 18 months |

Please call C.L. Smith Industrial Company and speak with your Sales Representative for your specific adhesive needs.

Speak With a Specialist

If you have an application to discuss, or need technical assistance, please fill out the form below.