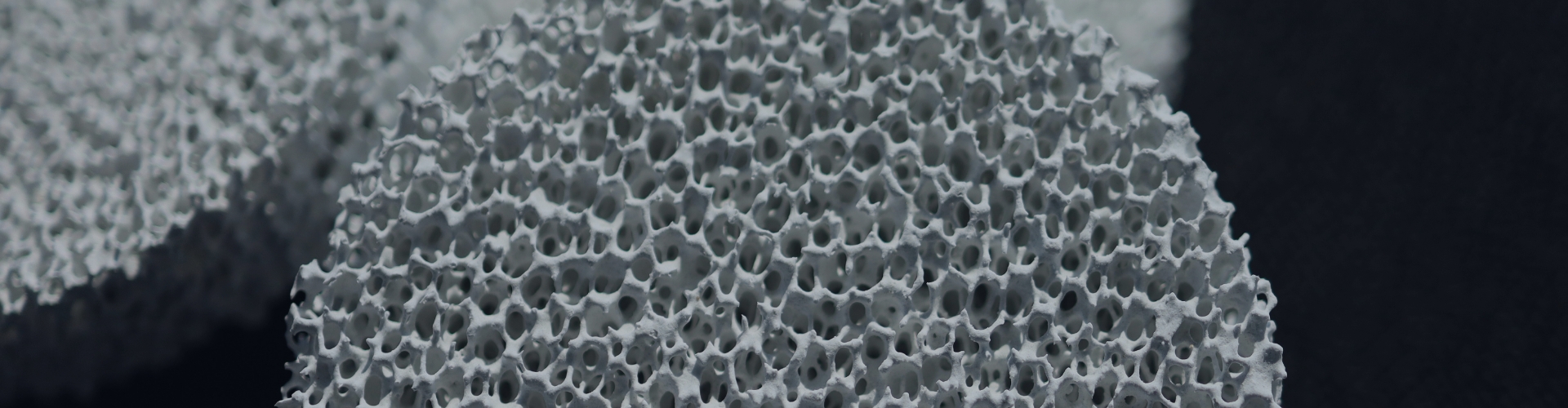

Porous Ceramic

For more than 40 years C.L. Smith Industrial Company has provided abrasion resistant solutions and teaming up with Filtros Limited, who has been at it for over 90 years, is a natural fit. Filtros Limited porous ceramic materials are ideal for specialty filtration applications encountered in today’s industrial environments. With exceptional physical, thermal and chemical properties Porous Ceramic can be used to filter any material that does not attack glass. With a variety of grades, pour sizes and abilities to custom compound and shape the media, Filtros Porous Ceramic can be used in many high performance liquid or gas filtration systems.

Applications

- Fluidized Beds / Air Slides for

- Drying and Heat Processing

- Blending and Separation

- Investment Casting

- Plastic Coating

- Underdrain plates for water treatment plants

- Potable water and tertiary sewage filtration

- High pressure/high temperature liquid and gas filtration

- Suction line filters

- Membrane supports

- Mining dewatering

- Liquid and gas chemical

- Hot gas articulate

- Food and beverage

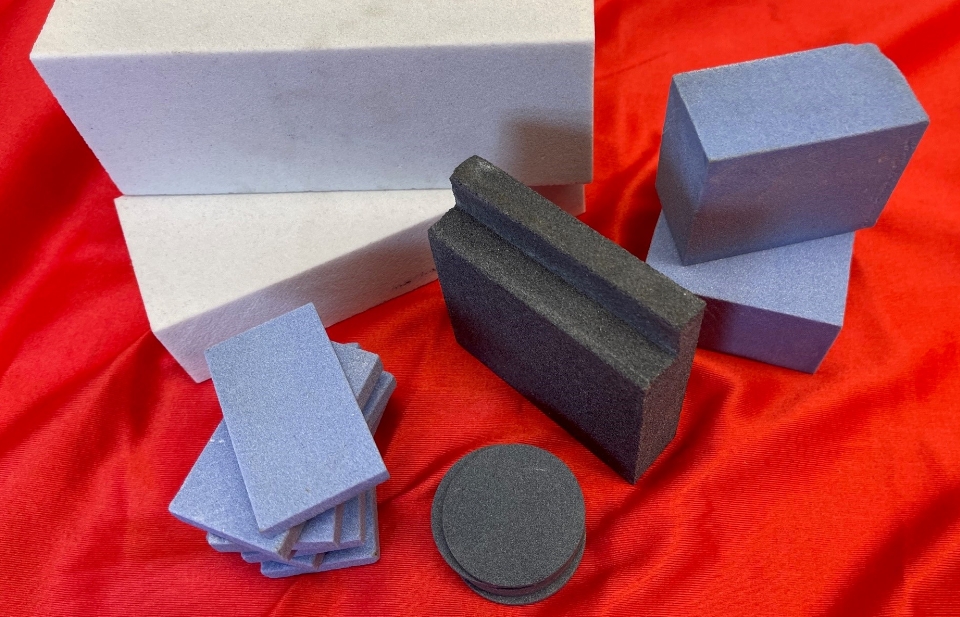

Materials

QF – Glass Bonded Silica

FAO – Ceramically Bonded Alumina

QR – Resin Bonded Silica

All materials are available in a variety of grades depending on your application. Resin bonded silica (QR) performs well in room temperature conditions with QR-130 fluidizing most materials. For higher temperature or special applications glass bonded silica (QF) or ceramically bonded alumina (FAO) are available in coarseness size to support the materials fluidization characteristics and volume of air available.

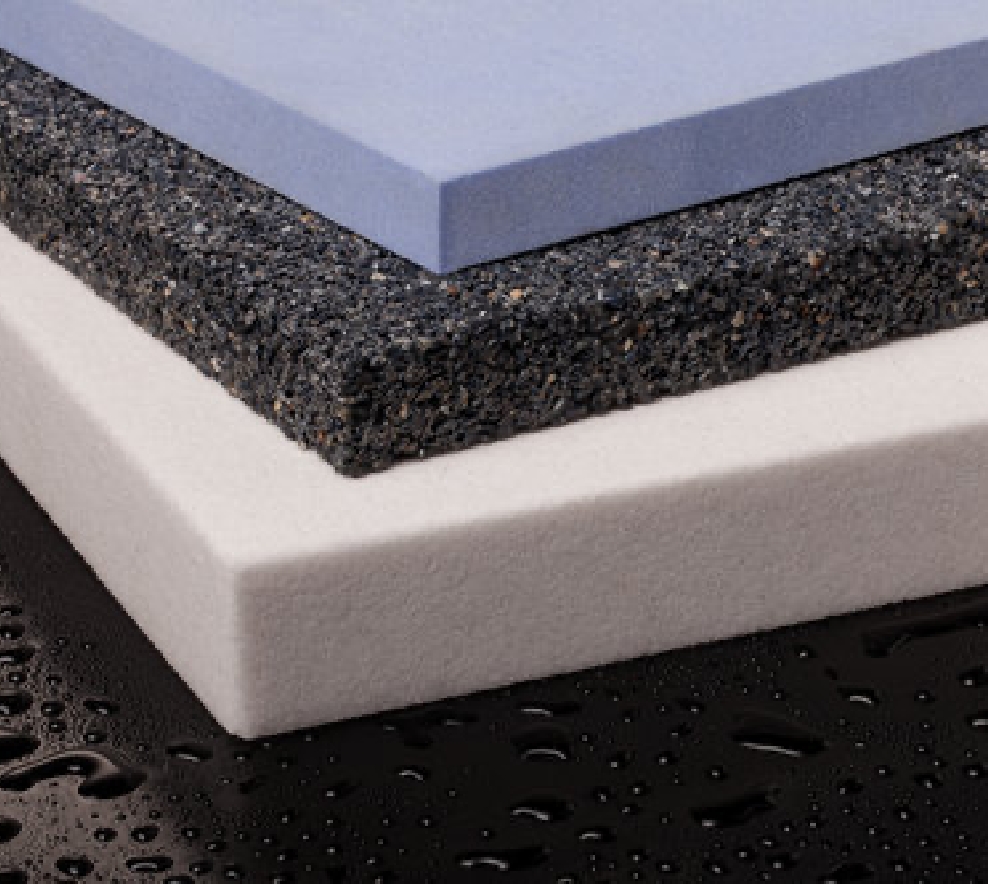

C.L. Smith Industrial’s performance blue Filtros Porous Ceramic plates are excellent for fluidized beds and an excellent alternative to cloth/fabric air slide material. Air is blown under the ceramic plate, diffusing it and the material above has minimal friction between particles which causes it to act like a liquid.

Material Grade

| Material Grade | FAO-10 | FAO-20 | FAO-30 | FAO-40 | FAO-50 |

|---|---|---|---|---|---|

| Nominal Particle Retention (μ) | 10 | 20 | 30 | 40 | 50 |

| Approximate Particle Retention (μ) | 1 | 2 | 3 | 4 | 5 |

| Maximum Pore Diameter (μ) | 60 | 80 | 100 | 120 | 140 |

| Porosity | 30-40% | 30-40% | 30-40% | 30-40% | 30-40% |

| Bulk Density (g/cc) | 2.1-2.3 | 2.1-2.3 | 2.1-2.3 | 2.1-2.3 | 2.1-2.3 |

| Flexural Strength (MOR) (psi) | 6,000 | 5,500 | 5,000 | 4,500 | 4,000 |

| Permeability @ 2" Water (cfm) | 2-3 | 3-5 | 5-8 | 8-12 | 12-15 |

| Material Grade | FAO-70 | FAO-100 | FAO-160 | FAO-700 | FAO-1200 |

|---|---|---|---|---|---|

| Nominal Particle Retention (μ) | 70 | 100 | 160 | 700 | 1,200 |

| Approximate Particle Retention (μ) | 7 | 10 | 20 | 100 | 200 |

| Maximum Pore Diameter (μ) | 170 | 210 | 300 | 800 | 1,300 |

| Porosity | 30-40% | 30-40% | 30-40% | 30-40% | 30-40% |

| Bulk Density (g/cc) | 2.1-2.3 | 2.1-2.3 | 2.1-2.3 | 2.1-2.3 | 2.1-2.3 |

| Flexural Strength (MOR) (psi) | 3,500 | 3,000 | 2,500 | 1,500 | 1,000 |

| Permeability @ 2" Water (cfm) | 20-25 | 35-45 | 70-80 | 120-140 | 170-190 |

| FAO-10 | FAO-30 | FAO-50 | FAO-70 | FAO-100 | FAO-160 | FAO-700 | FAO-1200 | |

|---|---|---|---|---|---|---|---|---|

| Inches Water (Pressure) | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 2.75 | 1.50 | 0.50 |

| CFM Air | 3.00 | 10.00 | 25.00 | 40.00 | 55.00 | 97.50 | 97.65 | 100.00 |

| FAO-1200 | FAO-700 | FAO-160 | FAO-100 | FAO-70 | FAO-50 | FAO-30 | FAO-10 | |

|---|---|---|---|---|---|---|---|---|

| Inches Water (Pressure) | 0.50 | 1.50 | 2.75 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 |

| CFM Air | 100.00 | 97.65 | 97.50 | 55.00 | 40.00 | 25.00 | 10.00 | 3.00 |

With the ability to convey large tonnages over long distances, reduced energy requirements versus other mechanical systems, minimal dust collection requirements and low maintenance costs the performance blue Filtros Porous Ceramic system is an excellent choice!

Speak With a Specialist

If you have an application to discuss, or need technical assistance, please fill out the form below.